By definition, a K-type thermocouple is a thermocouple that uses Chromel and Alumel as conductor legs and has met the standard output requirements as stipulated in ANSI/ASTM E230 or the IEC 60584.

Off the bat, the K-type thermocouple is the most popular thermocouple type. Indeed, it’s hard not to talk about this thermocouple without using superlatives. You could say it’s the star of the show. Further, the use of K-type thermocouples has gained traction in light of the fact that thermocouples are the most widely used temperature sensor worldwide. Any industry leader worth his name in salt would stand to benefit a lot knowing this thermocouple’s unique characteristics. Making the most of it in the process.

By the same token, anyone who wants to become an industry leader but does not have a firm grasp of this trailblazing thermocouple would be in a disadvantaged position. It’s paramount therefore that we get down to the nitty-gritty. And separate fact from fiction, an approach touted by no less than the richest engineer billionaire on the planet Elon Musk. Such a first-principles approach should bid us well. This is especially true for the type K thermocouple where the applications can be most varied and most beneficial.

What is a K-type Thermocouple Made of?

Take note. The telltale sign that you’re handling a K-type thermocouple is its legs. It must be made of chromel and alumel. Know that both chromel and alumel are nickel alloys. Chromel (90% nickel and 10% chromium) is designated the positive leg while alumel (95% nickel with 2% manganese, 2% aluminum, and 1% silicon) gets the negative leg.

Both these nickel-based alloys are sturdy, reason enough why K-type has risen to the top. By and large, these metals are also cheap.

It must be emphasized, however, that for you to max on a K-type thermocouple, it must adhere to consensus-agreed standards such as ANSI/ASTM and IEC.

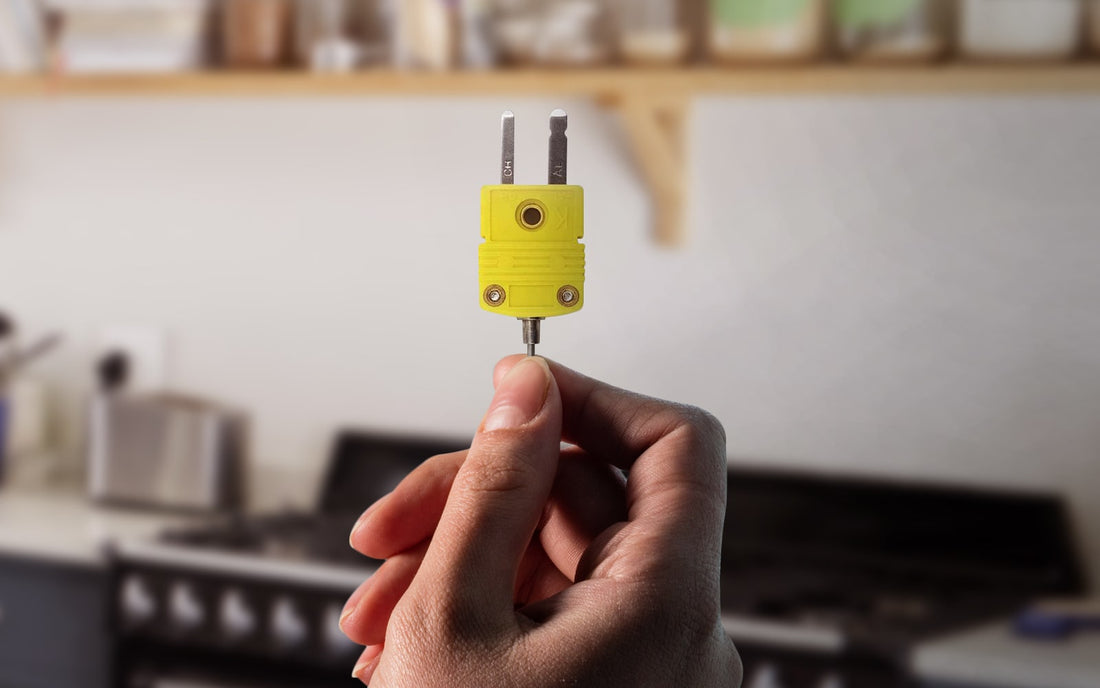

K-Type Thermocouple Color Codes

|

International Standard |

Positive Leg (non-magnetic) Wire Connector Color |

Negative Leg (magnetic) Wire Connector Color |

|

ANSI/ASTM |

Yellow |

Red |

|

IEC |

Green |

White |

To note, ANSI is American National Standard Institute that oversees and ensures there is a voluntary consensus standard implemented for industry products and processes. ASTM or the American Society for Testing and Materials is an international standards organization that is under the umbrella of ANSI. IEC (International Electrotechnical Commission) is similar to ANSI but of French or European origin.

Making sure your K-type thermocouple has passed these standards is an assurance that you’re working with safety in mind. Best of all, you’re assured your industry processes will not be undermined by a faulty temperature sensor.

So assuming you’ve already had some groundwork knowledge on thermocouples, we won’t be dwelling too much on how thermocouples work. Instead, we encourage you to take the time and read the How does a Thermocouple work blog here.

What Makes It Most Useful

It’s good to note that there are other thermocouple types that can outperform K-type thermocouple in certain aspects. N-type, for instance, can operate at a wider temperature range. Plus, it’s perfect for nuclear situations being able to resist oxidation better in the hottest of environments. With one drawback. N-type costs more.

Overall, however, K-type thermocouple’s characteristics are tough to beat. Quite simply, it’s a lethal combination that fits the needs of a wide range of applications for many industries. Nickel-based alloys display strong resistance to oxidation and corrosion.

The wide temperature range characteristic of K-type serves many industries more than any thermocouple type. Further, the device is robust especially when paired with a metal-insulating cable. The setup can give you readings at higher temperature ranges.

The response time is quick and laudable. Even better, you can deploy K-type in harsh environments that would make far lesser sensors fold. Mineral-insulated variety for instance is impressive. They can produce quality output even in vibration-prone unstable environments.

What is the Range of K-type Thermocouple

As a general rule, type-K thermocouples can measure a temperature range of -326 to 2300°F or -200 to 1260°C. Not every K-type can exhibit such a wide range, however. Special attention to the device must be given when made to perform at extreme temperatures:

- At freezing point for instance (32°F/0°C/273.15°K), special materials must be incorporated for the device to not stray away from a reliable reading.

- As for hotter temperatures, the ability of K-type to measure is dependent on how big the size of the deployed conductor is.

K-type Wire Dimensions and Maximum Target Temperature Measured

|

Maximum Target Temperature |

Wire Gage |

Diameter |

|

760°C/1400°F |

#30 AWG |

0.010” |

|

870°C/1600°F |

#28 AWG |

0.013” |

|

870°C/1600°F |

#24 AWG |

0.020” |

|

980°C/1800°F |

#20 AWG |

0.032” |

|

1090°C/2000°F |

#14 AWG |

0.064” |

|

1280°C/2300°F |

#8 AWG |

0.128” |

Now, you could be wondering how big is the voltage produced by a K-type thermocouple upon the measurement of various temperatures. Know that there’s a slight variance from one thermocouple to another depending on a host of external and internal factors.

In general, however, these are the voltages produced when the thermocouple measures the following temperature ranges.

An Overall View of K-type Voltage Amount Produced per Temperature Reading

Considerations and Limitations

As much as possible, do not engage K-type thermocouples in conditions that have not been tried before. If you want to experiment on certain physical setups, do your due diligence first for the best results.

For one, type-K is vulnerable to sulfur attack. An example scenario would be the burning of fossil fuels or the smelting of sulfur-rich mineral ores. You cannot deploy this thermocouple type in these setups and expect reliable numbers.

Another limiting factor is partially-oxidizing conditions such as in a vacuum. The same holds true for environments where the oxidation is alternating and not fully functional.

With that said, do not deploy K-type in reducing atmospheres. Simply put, reducing atmospheres is an atmospheric condition devoid of oxygen. In its stead, reducing gases such as hydrogen, carbon monoxide, and hydrogen sulfide.

Reducing atmospheres are used in metal processing. Annealing ovens to relax metal stress is one example. Also, such an oxygen-less atmosphere is used to produce special effects on ceramics.

Commercial incinerators also make the most of reducing atmospheres to hasten the release of carbon-bearing fumes.

Compared to thermocouples made up of noble metals (B, R, and S), type K can age their emf character faster. Giving out erroneous results.

Know that type K has a sensitivity of 41 microvolts per degree centigrade. It’s a manageable variance. However, there are ways you can maximize type-K thermocouples in particular.

Just like any thermocouple, ensuring you have them calibrated right before use is best. As the voltage output is very minimal, noise can be an issue. And as the years go by, thermocouples become prone to strain and corrosion.

Still, its use has been most reliable compared to the other thermocouple types. Indeed, if there’s a thermocouple that has carried the industry more than most, the K-type thermocouple has done that best.