Be forewarned. While ungrounded, grounded, and exposed thermocouple junctions have the same purpose, both are designed to operate in totally different environments. Simply put, not minding that spells disaster.

In a corrosive environment where speed is paramount, a grounded type works best. Otherwise, if you put a premium on greater accuracy over the speed of temperature acquisition, then an ungrounded thermocouple is the better choice. As for the exposed type, it’s best when you want to obtain data the quickest but only in stable environments.

Confused? Don’t fret. In this post, we are going to show you the details you need to determine if you should use a grounded, ungrounded, or exposed thermocouple junction for your application.

What’s more, we’re doing a side-by-side comparison of the three thermocouple junction types, exposed junction including, so you won’t run into messy complications and cry over failed projects when choosing the best thermocouple types for your business. Read on.

An Introduction to Thermocouple Junctions

More than any temperature sensor, thermocouples have been the choice for the most challenging applications on the planet, from high temperatures to high-vibration applications.

Essentially, thermocouples are just two dissimilar metal conductors connected together to form an electrical junction. By having two distinct metals meet, the Seebeck Effect where a temperature-dependent voltage that can be measured happens.

At its core, therefore, there are three main components of a thermocouple, namely the two metals and the point where each one meets called the junction.

(Fig. A) Thermocouple without and (Fig. B) and with insulator.

These three components are then covered by an insulator and an overall metal sheet so the wires and the junction are protected. So, as in the actual product offerings, you don’t actually see the two-wire junction as it’s all covered in a protective sheath.

Grounded vs Ungrounded Thermocouple Junction

Right off the bat, know there’s no such thing as a superior thermocouple junction type. Both grounded and ungrounded have their own advantage and disadvantages that make each one ideal for a specific application, or a specific task.

For many instances there, user complaints about inaccurate readings or electrical noise disrupting their measurements and causing alarm were really about bad choices on which thermocouple junction type to use.

To be able to discern which type should be most advisable for you, let’s start with a little understanding of how each type of thermocouple junction works and their advantages and disadvantages. And take it from there.

The Case for Grounded

A thermocouple is grounded if the junction has been welded directly into the protective sheath located at the tip of the sensor. Such a design allows the measurement of the temperature to be done quickly as the metal-to-metal connection ushers in a shorter thermal route

Fig. C: Grounded Thermocouple Diagram

With that said, let’s take a peek at what makes grounded a suitable junction for your application.

So, the biggest advantage you have when using a grounded thermocouple junction type is speed. It’s best, therefore, when you are dealing with largely unstable environments where you need to extract the temperature data as quickly as possible. Top of this list is high-pressure or corrosive environments.

However, there’s a disadvantage. Grounded thermocouples are susceptible to noise more than their ungrounded counterparts. This can lead to less accurate readings.

The reason for this is simple. Welding the junction to its sheath creates an electrical connection between the two metals, namely the sheath and the wires. Such a setup can result in unwanted side effects when certain conditions are present.

For instance, grounded thermocouple junctions can lead to a “ground loop” in cases when the sensor has been connected to earth ground at the point of measure. Also, this happens if the wires are connected to a controller that has been grounded at a separate location.

The Case for Ungrounded Thermocouple

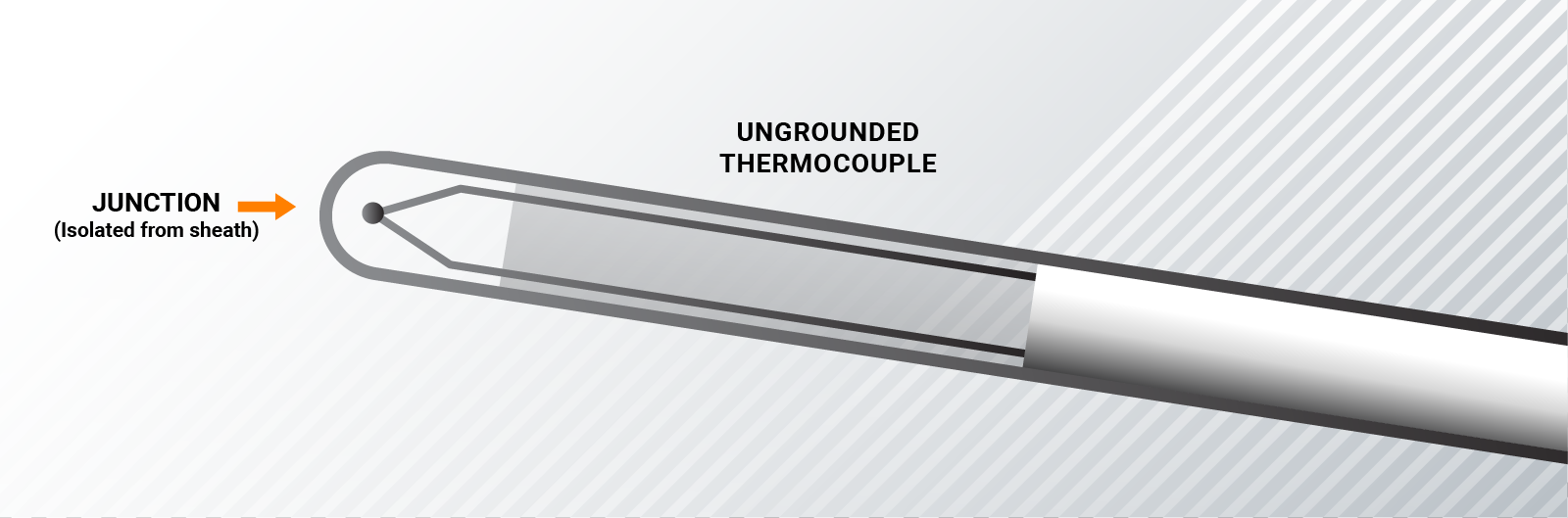

Unlike grounded, an ungrounded thermocouple is not welded directly to the sheath. It means it’s isolated from the protective sheath. Such a setup translates to a more accurate reading when taking up corrosive environments — albeit for a longer time.

Usually, a non-conductive powder such as magnesium oxide is used to surround the junction at the tip of the sensor. The chemical material effectively provides a buffer by slowing the thermal transfer between the media being measured and the junction.

Fig. D: Ungrounded Thermocouple Diagram

The isolation means ungrounded is less susceptible to electrical noise than grounded. Here’s a deeper look at its strengths.

If you’re prioritizing reading accuracy over reading time, then the ungrounded is the best choice for you. The thermocouple here is protected from electrical noise that could happen if it were connected to the sheath. The distance, therefore, plays a central role in giving an ungrounded junction type better accuracy.

This junction type is best for very low-level signals. Ungrounded is also best for corrosive environments where you need to measure temperature in a much more accurate manner than in grounded-type settings.

Grounded and Ungrounded Thermocouple Sample Applications

Both grounded and ungrounded thermocouples are best for corrosive environments. The only difference is your purpose. If you choose to prioritize accuracy then use ungrounded, but if you need faster readings then grounded is your best bet.

Corrosive gases are not to be trifled with. They can attack and subsequently damage human tissue. But that’s not all. They’re so destructive they could damage metal and a slew of building materials.

If you’re wanting to measure the temperature of these gases, then using a grounded thermocouple is best as you can take the measurement quickly. On the other hand, you should use ungrounded if you want more accurate readings.

The list of toxic and corrosive gases includes ammonia, chlorine, hydrogen chloride/ bromide, and nitrogen dioxide. Industries in the oil and gas usually deal with these harmful gases.

Needless to say, high pressure put any measuring instrument under undue stress. Not only should they have sensitivity but must also be robust to withstand the pressure.

Usually, these high-pressure environments are found in the manufacturing business. Top of the list is furnaces, stoves, and pizza ovens.

Exposed Thermocouple: The Third Alternative

With that settled, let’s take a look at another thermocouple junction type to widen your choices: exposed thermocouples. Know, first-hand, that this type is the fastest of the bunch.

The Case for Exposed Thermocouples

You can easily determine an exposed junction thermocouple by looks alone. That’s because, as its name suggests, exposed ones have the thermocouple junction out of the sheath protruding and visible like a big, fat, sore thumb.

Fig. D: Exposed Thermocouple Diagram

Such a setup is the best choice if you want to have the fastest method to read temperatures in an application. But it’s also fit in non-corrosive environments as it’s the most prone to noise.

If you’re prioritizing reading accuracy over reading time, then forget about exposed junction thermocouple. The biggest advantage you have here is the speed of delivery. If you want the fastest reading time, then there is no question. Hands down, exposed junction wins overall.

But this type is meant only for stabler environments. This means that this type cannot be used for high-pressure environments or corrosive ones.

Exposed Junction Sample Applications

Think of an exposed junction as a person with a sanguine personality. It can function best when there is a lot of stability in the environment. In short, this type can get the job the quickest but as its junction has no protection, it can’t deal with challenging circumstances.

Noncorrosive Environments

We have to bear in mind that the junction here is unprotected. Unlike grounded and ungrounded, you don’t have a protective sheath to ward off the noise. So, if you’re looking at having the quickest response time in reading the temperature, this is your guy, but only if you’re dealing with low-risk environments.

So never use this type in toxic gases, toxic chemical liquids that can bring immediate damage to the junction. Or else you damage the thermocouple and ultimately won’t be able to measure the temperature.

Low-pressure Applications

The same holds true here. High heat and anything that can easily put the junction in danger is a no-no to an exposed thermocouple. With that said, this type can measure non-corrosive static liquid, gas, or air.

Top FAQs for Thermocouple Junction Types

How do I know which thermocouple junction type to use?

Determine if you have a corrosive or non-corrosive environment to know which thermocouple junction type to use. Grounded and ungrounded junctions are best for corrosive while exposed is best if you prioritize speed of measurement most.

How do I determine a ground loop?

Unstable readings are one of the best ways to know a ground loop. When your measuring instrument becomes susceptible to changes in the weather or if it smokes and is electrically damaged, then a ground loop is most likely.

How do I prevent a ground loop?

Using an ungrounded thermocouple is the best way to prevent a ground loop. Also, make sure you have but one ground in your instrument loop. So either you ground the transmitter or you ground the controller/recorder but never ground both.

In Summary

Fig. F. The Three Main Types of Thermocouple Junctions

So, there you have it. Thermocouples are a most useful bunch. But to make the most of it, you need to have the best thermocouple junction to fit your application. For the most accurate you have ungrounded but for speed, you have exposed and next comes grounded.

When choosing the most reliable thermocouples, reliability is a must. Over time, customer satisfaction points to one thing: thermocouples that last.